Leyland P76 Owners 2003 |

Technical |

COOLING SYSTEM STUFF

by Jilden

DEFINITION: Automotive coolant is water with corrosion inhibitor added.

- Every so often I go off the deep end at someone who hasn't been listening to me about the dangers of buying their coolant/corrosion inhibitor based on a recommendation "for older cars".

- You must remember, it’s in the Industry’s interest to get your "older car" off the road as fast as possible.

- Every square millimetre of the inside of your precious P76 engine that is made of highly reactive aluminium will suffer for your lack of care.

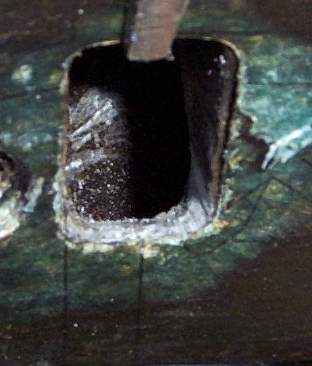

- To illustrate what happens when you use poor grade corrosion inhibitor, look at this:

- Cavitation occurs when a pump runs at high RPM and the cooling system isn’t at full pressure.

- This means either the engine is cold, or your radiator cap is faulty.

- Cheap coolant works by causing a hard black Phosphate coating to form on the surface of the aluminium.

- During cavitation, this layer is knocked off the aluminium by imploding vapour bubbles.

- A new layer has to form, using up a small amount of metal in the process.

- Over a few months, this can destroy a water pump or a timing cover.

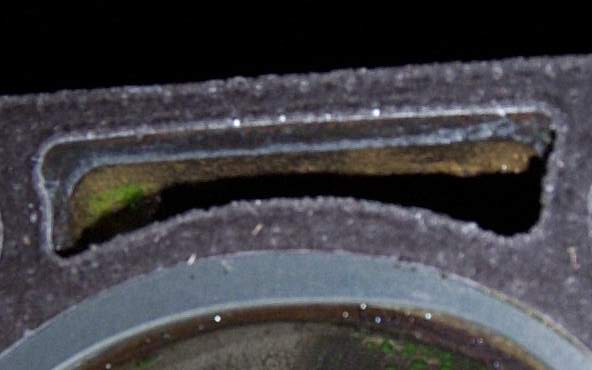

- The coolant also relies on oxygen being present in the coolant.

- Where oxygen is lacking is under hose clamps:

- Cavitation occurs when a pump runs at high RPM and the cooling system isn’t at full pressure.

- This means either the engine is cold, or your radiator cap is faulty.

- Cheap coolant works by causing a hard black Phosphate coating to form on the surface of the aluminium.

- During cavitation, this layer is knocked off the aluminium by imploding vapour bubbles.

- A new layer has to form, using up a small amount of metal in the process.

- Over a few months, this can destroy a water pump or a timing cover.

- The coolant also relies on oxygen being present in the coolant.

- Where oxygen is lacking is under hose clamps:

Moth eaten pump inlet with a hole right through near the body.

- This type of damage is usually slower than cavitation damage, but none the less, a 30 year old pump won’t be re-buildable if you don’t look after it.

- The warning sign with this kind of damage is a large bulge immediately behind the hose clamp, as the aluminium rots away.

- So how DO you tell whether your coolant is any good?

- Put on a new thermostat housing, run the car for a few months, and then pull off the radiator hoses and the housing.

- Look for a black layer inside and powdery corrosion on the outside.

- This is a sure sign that you are risking the life of your engine.

- Now for some other issues: how to keep your P76 running at a happy temperature.

- For maximum life, the P76 should run at between 80C and 90C.

- Below 80C, the oil tends to not evaporate any contaminants, and above 90C the head gaskets tend to weaken as the alloy ‘walks’ with the higher expansion.

- P76 V8’s run at 100C or higher tend to expand enough for the cylinder liners to come loose and rattle hideously.

- I have met this problem quite a few times, especially with P76 V8’s fitted to Range Rovers.

- A lack of cooling power is fatal to the press fit of the cylinder liners.

- How to keep your P76 warm? Simple, fit a thermostat, at 80C or higher.

- To keep it cool is another matter. Some tips are as follows:

- Head gaskets can partially overlap the water jackets at the back of the block:

- Casting dags can block the same passage. Look at the left of the picture:

- The inlet manifold is usually a poor fit on the head water ports. The lower edge partially blocks flow into the manifold.

- If the port is opened up to gasket

- size, water flows much easier :

- Original: ported out to gasket size:

- Engine fans should partially protrude from the back of the shroud.

- This allows air to flow from the tips of the fan, and pass to either side of the engine:

- A standard fan will work in traffic when the fan spacer is shortened by 25mm or so, as in the picture of a standard P76 above.

- A viscous fan drive from a Holden, when fitted to the P76 V8, will have enough rearwards offset to cool at slow road speeds.

- The Holden fan coupling needs to have the bolt pattern altered with a sharp round file or rotary burr, as the P76 bolt pattern is slightly smaller.

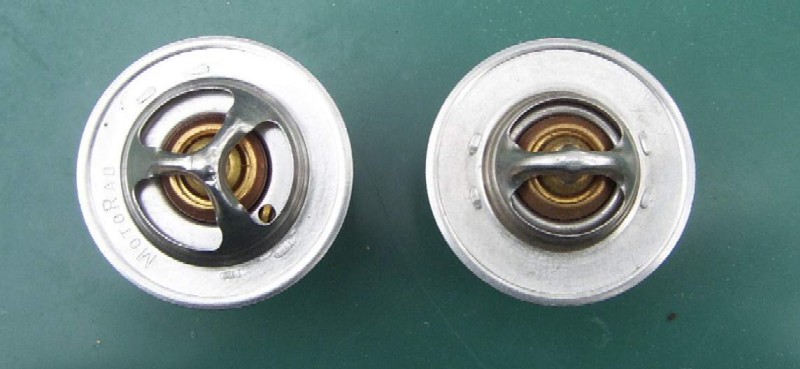

- Water flow can be improved by fitting a high flow thermostat, such as the Tridon part no. TT2000-180 one pictured overleaf on the left.

- The manufacturer claims 30% more flow.

- A standard one is on the right.

- The best fit core for a standard P76 radiator, enabling it to look absolutely original, is a three row one specified for a Nissan Bluebird RWD sedan.

- It is the same height and tank plate size as the original P76 radiator.

- My experience with this type of core is that it is very efficient.

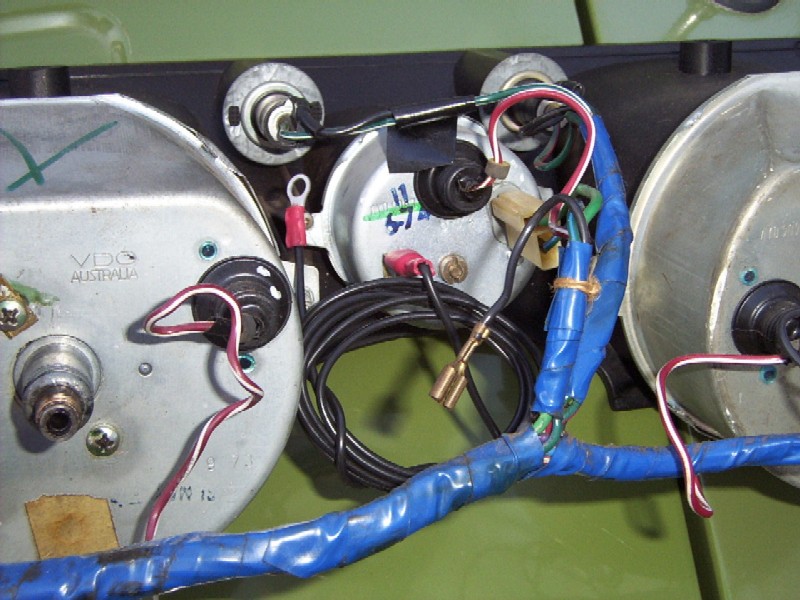

- Last but not least, some P76’s have temperature gauges that get higher when you turn on the headlights.

- The reason being, the factory earthing between the gauge and the engine block isn’t sufficient.

- As current flows, the gauge gets false signals.

- You can replace the engine earth cables under the bonnet, as this helps with headlight brightness anyway.

- I prefer to also add an independent earth wire from the temperature gauge to the top of the carby or manifold somewhere.

- Now the gauge will only respond to changes in temperature, not electrical load.

- Remove the existing earth wire and tape it up. Replace it with 1.2m of wire with a female connector for the gauge.

- Fit a ring terminal to the other end and connect it to the top of the engine.

- The wire is coiled up in the picture to show both ends.

- Jilden

This site is hosted on

Freeservers  Reliable, Free Web Hosting |

Last updated July 2018 |

This web site may contain Copyright material If you find any problems with the site, please email the Web Editor  |